Wheel Sorter

Home » Sorter Machine » Wheel sorter

Introduction

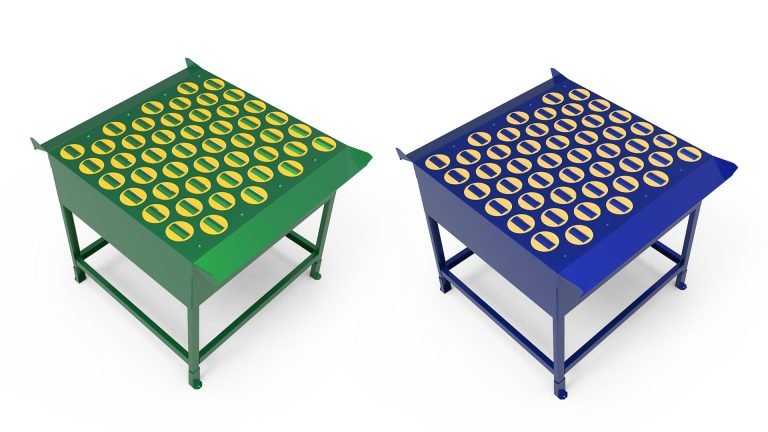

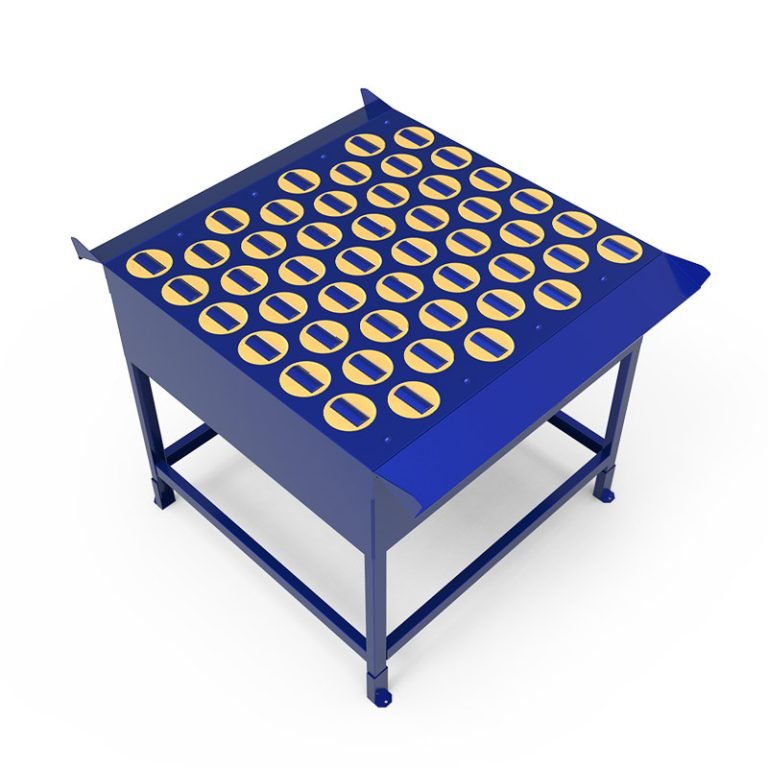

Also known as inclined guide Wheel Sorter, deflected wheel sorter, modular wheel sorter. It is a sorting equipment that drives the direction of the sorted items by changing the direction of the rollers on the contact surface to achieve the purpose of sorting. The wheel sorter is more used in unloading rough sorting, bulky sorting, heavy sorting, scanning loading and other links. It has the characteristics of high efficiency, high accuracy, high load capacity, light application, and zero loss in sorting.

Model: Sorter Machine

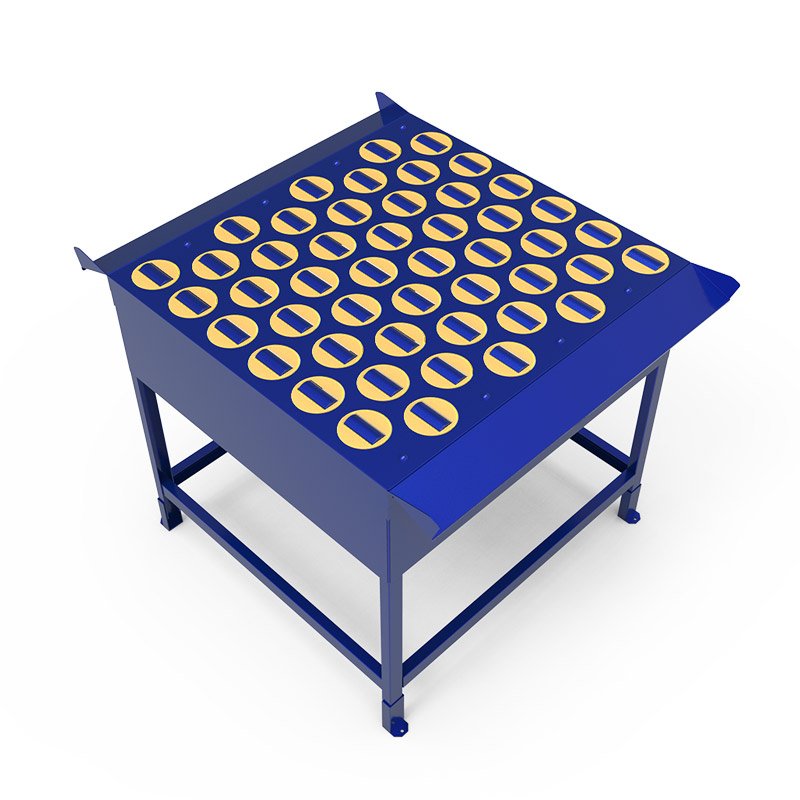

It is mainly composed of fully modular independent wheel, synchronous steering controller, transmission device, frame and so on.

What are the characteristics of the equipment

1. Modular design, each wheel is an independent module, which can flexibly adjust the number of wheels according to the actual application needs of users, so as to realize the adjustment of the length of the conveying surface and the width of the sorting surface of the wheel sorter.

2. Low noise, quiet design, the noise is as low as 60 decibels (about the same as the normal speaking volume).

3. Easy to maintain, a one person can complete the maintenance or replacement of the wheel module within 10 minutes.

4. Easy to integrate, a one person can complete the integration within 5 minutes.

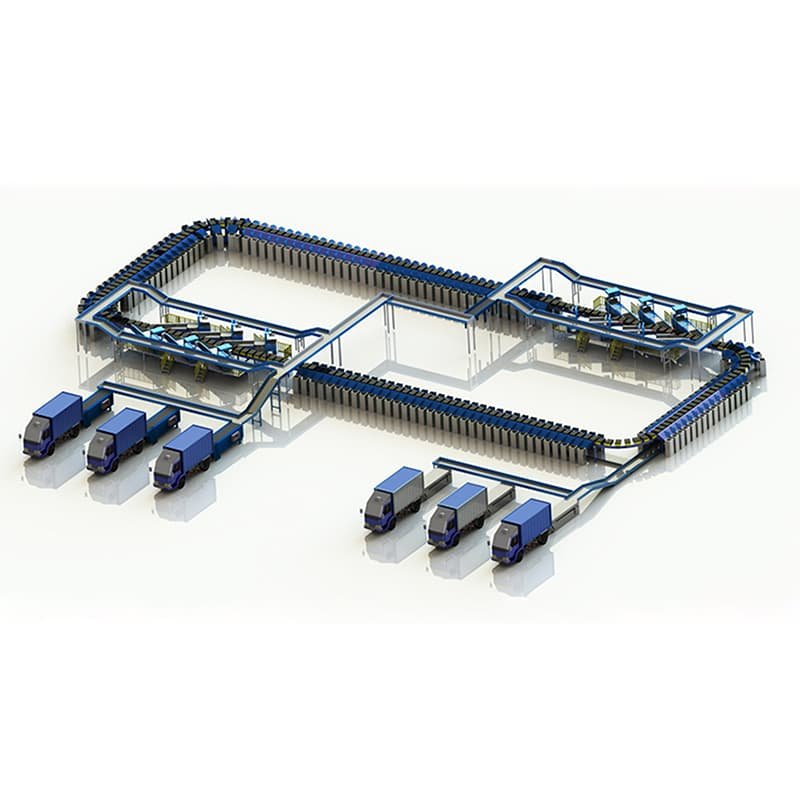

5. Flexible matching, a single device covers an area of less than 1 square meter, and can be combined freely

6. Short payback cycle”

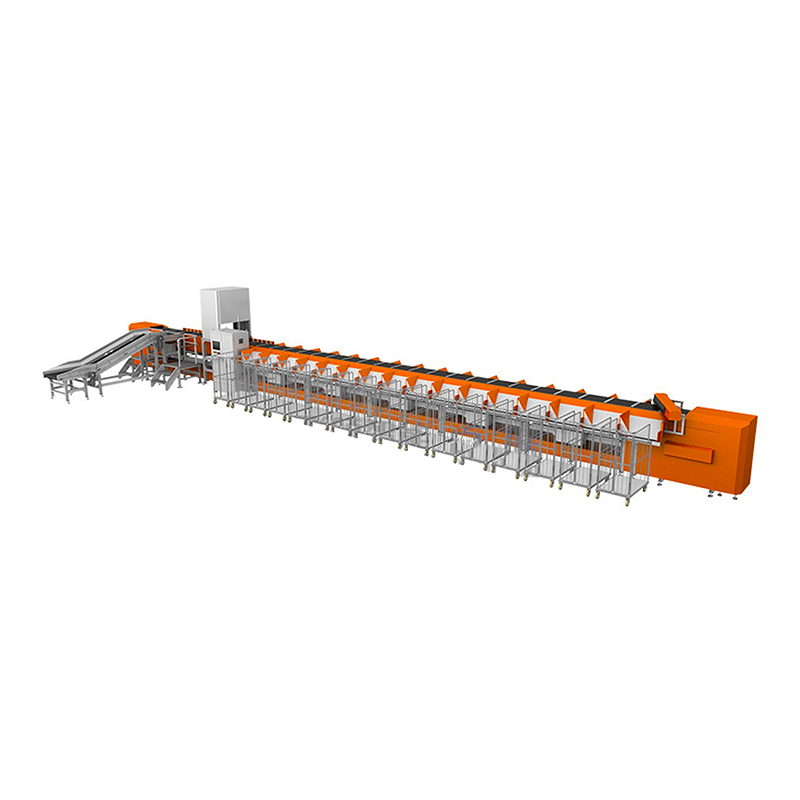

E-commerce, express delivery, postal service, fresh cold chain, distribution center, food, beverage, medicine, 3C, electronics, daily chemical and other industries

Scenarios such as rough sorting of express unloading vehicles, large express packaging vehicles, food, beverages, production lines, and airports

During operation, according to the instructions and information issued by the management system, the steering controller changes the running direction of the conveying rollers, which can realize the sorting of items on the left and right sides, and transfer the items to the diverted conveyor.

During operation, according to the instructions and information issued by the management system, the steering controller changes the running direction of the conveying rollers, which can realize the sorting of items on the left and right sides, and transfer the items to the diverted conveyor

1. It is suitable for sorting heavy and large items. It can bear the sorting of heavy items up to 50kg, and the maximum package size can reach 1200x 1000 x 800mm.

3. Flexible sorting, reducing damage. The wheel sorter is connected with the belt, and the rollers are wrapped with rubber, so the conveying action is soft and the goods will not be lost.

4. Independent module, low failure rate. The wheel sorter adopts a structural design, each wheel is a separate module, and the failure rate is extremely low. Even if a failure occurs, the module repair or replacement can be completed within 10 minutes.

5. The sorting speed is fast and the error is low. 3000-6000 pieces/hour, wheel sorting and use barcode technology to identify packages, the error rate is only one in a million.