Loop Crossbelt Sorter

Home » Sorter Machine » Loop Crossbelt Sorter

Introduction

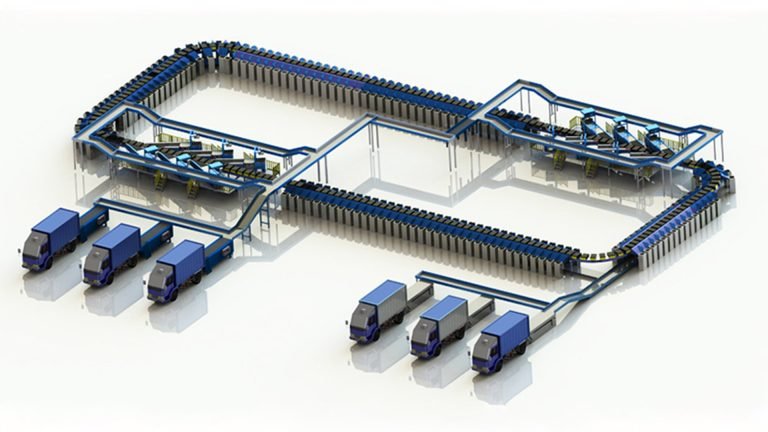

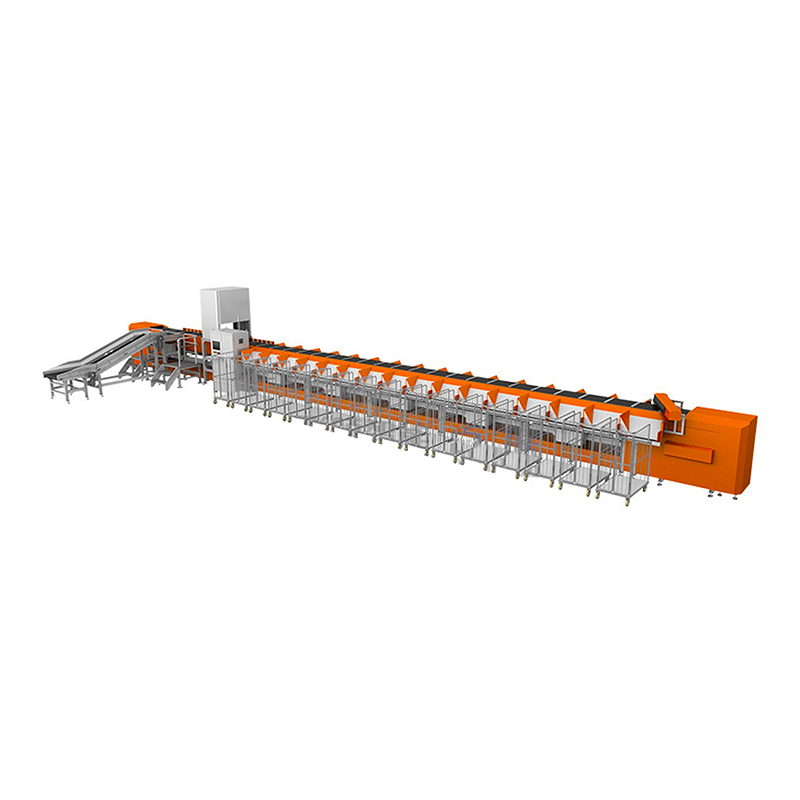

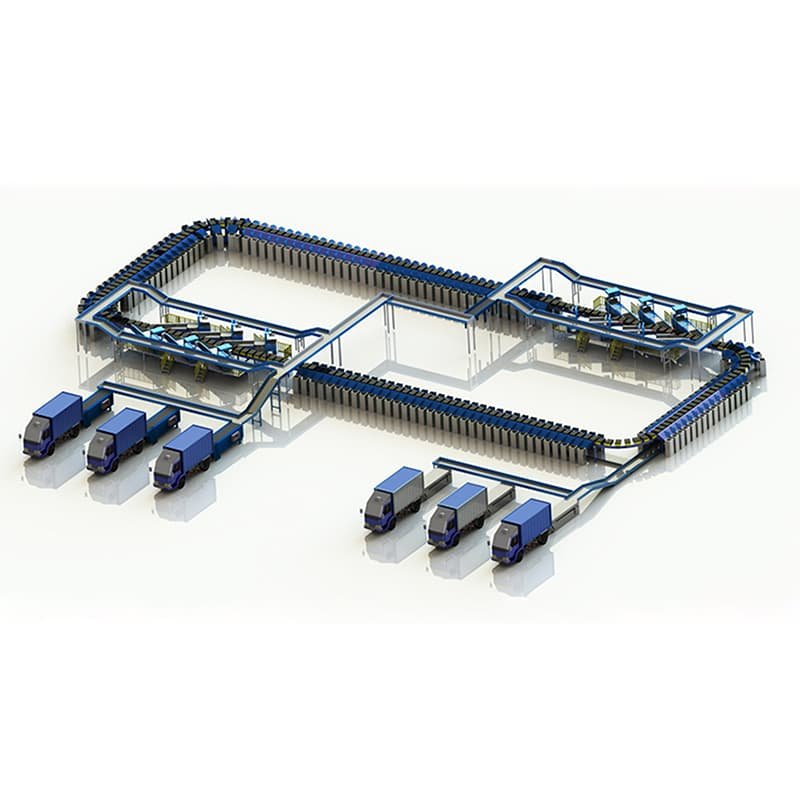

The loop crossbelt sorter is mainly composed of four parts: the supply system, the sorting trolley, the parcel off-loading system and the control system. Under the coordinated control of the control system, the parcels are imported from the supply system into the sorting trolley for sorting, and the parcel off-loading system completes the physical location of the parcels for sorting storage, thus achieving the parcel sorting function.

There are three types of lines that are widely used, namely single-layer single trolley sorting systems, double-layer single trolley sorting systems, and single-layer double trolley sorting systems

Model: Sorter Machine

Generally, it consists of four parts: supplying system, sorting trolley, parcel off-loading system and control system.

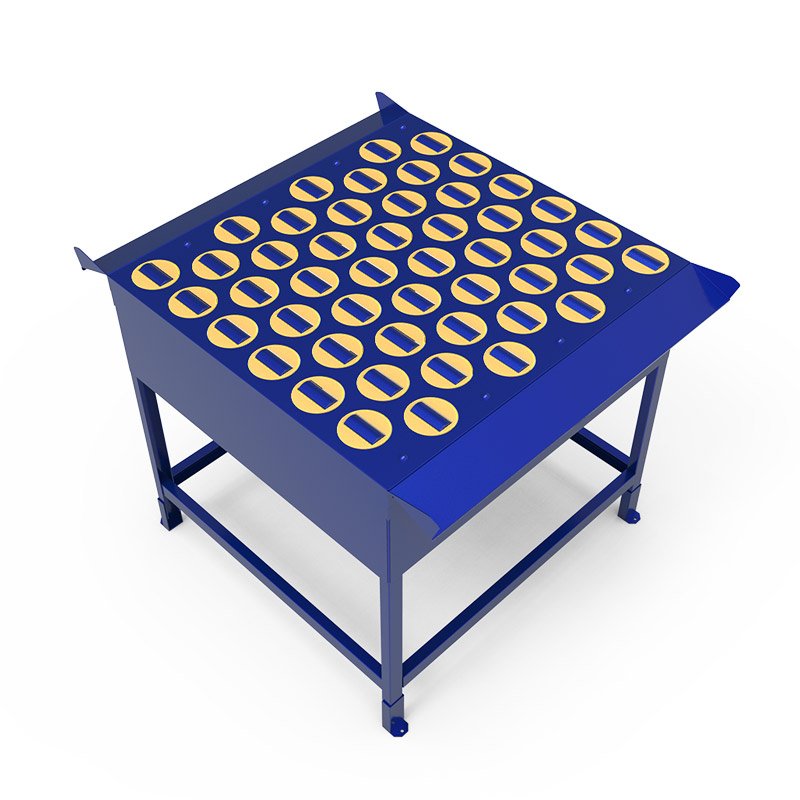

Supply system: generally consists of a three-stage/four-stage package supply station (package supply station with scanning, weighing and measurements), with a single supply station efficiency of about 1300-1500 pieces/hour; it is also possible to manually load packages (top scan) and place them directly on the trolley for sorting;

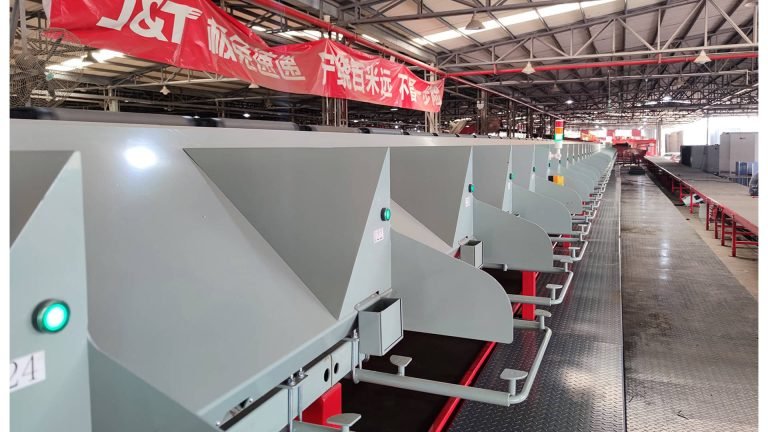

Sorting trolley: consisting of a trolley and a trolley track;

Parcel off-loading system: port (750mm), port electrical, port photoelectricity (full port detection), bag collection/cage carriage

Control system: designated configuration server (picture/data, sorting/local cache); Siemens PLC, server data interaction processing, sorting control system; equipment detection, fault diagnosis, maintenance reminders, etc.; operation parameter setting, remote management, data statistics, etc.; IT-level network supporting equipment, data docking; interconnected intelligent gateway system; WEB server network system; industrial network data exchange systems

Postal, Express, E-Commerce

The parcels are placed manually, the scanning system gets and uploads the barcode information to the headquarters server, the headquarters feeds back the parcel drop grid information, the parcels enter the sorting trolley through the package supply platform, the sorting trolley runs on the track, runs to the designated port, slides the trolley belt left and right, and drops the parcels into the designated port for collection.

1.Compact structure, small footprint ;

2.Reading code accurately, scanning code weighing integration, save time ;

3.Sorting a wide range of parcels, high sorting efficiency, low misclassification rate ;

4.Sorting action is gentle, the impact on the goods is small ;

5.durable, low noise, cost-effective, convenient installation and maintenance ;

6.Strong adaptability and flexible configuration. It can connect with various information management systems of customers and customize functions according to user needs.

| Car control electrical Panasonic sliding contact line \ brush \ collector, etc. (25/28 \ group) |

|---|

| Panasonic slide rail, Leisai/Hongma/Shengpai 5.5KW linear motor, Leisai/Hongma/Shengpai 400W 48v electric roller, Kinco (Jintaiyuan) servo drive, Seabeck 700×428 belt; H1800 intelligent carrying tray ;Flexible organ cover; L3000mm track; Gantry frame Top Scan Hikvision (single camera) |

| Software control/main control cabinet Siemens/Danfoss inverter; Huawei/tplink thousand M switch; Jinhuanyu transformer sorting and handover control cable; Dell WCS designated configuration server (picture/data, sorting/local cache); Siemens PLC, Server data interactive processing, sorting control system; equipment detection, fault diagnosis, maintenance reminder, etc.; operating parameter setting, remote management, data statistics, etc.; IT-level network supporting equipment, data docking; interconnected intelligent gateway system; WEB server network system ;Industrial network data exchange system; Industrial upper computer_PC (Lenovo/Dell); SQLsrever database; |

| Wireless communication Wireless AP; Siemens PLC communication interaction detection, feedback sensing, power supply, etc. |

| Main line speed 1.8-2.5m/s |

| Weighing function Static weighing of the package table (dynamic weighing can be upgraded) |

| Maximum sorting efficiency 13200 votes/hour |

| Weighing range 10g-10Kg |

| Trolley size 426mm*700mm |

| Trolley pitch 600mm |

| Grid width 750mm |

| Sorting goods size range 10*50*50-200*400*400mm |

| Sorting accuracy rate 99.99% |

| Controller A full set of Siemens controller solutions (1500, 1200 series PLC)Loop Drive Linear Motor (Electromagnetic Drive) |

| Trolley drive mode Motorized drum Servo drum |