Linear Cross Belt Sorter

Home » Sorter Machine » Linear Cross Belt Sorter

Introduction

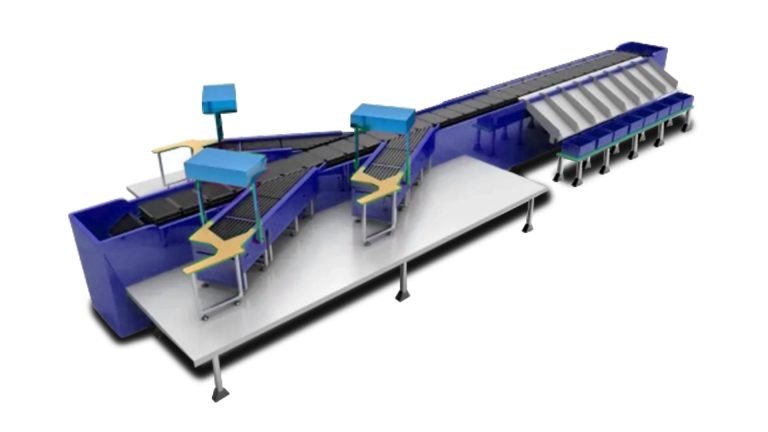

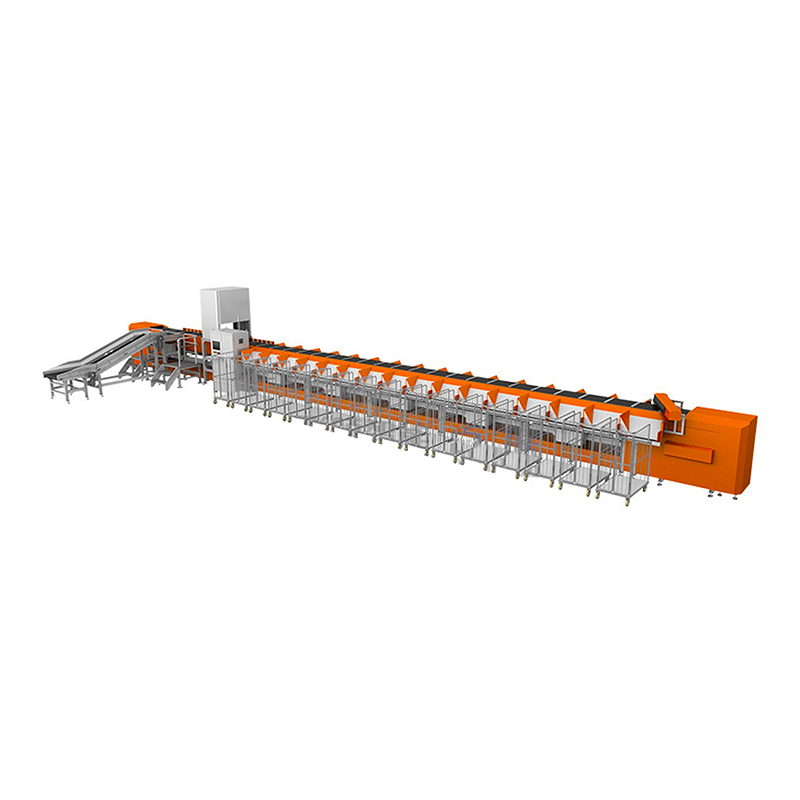

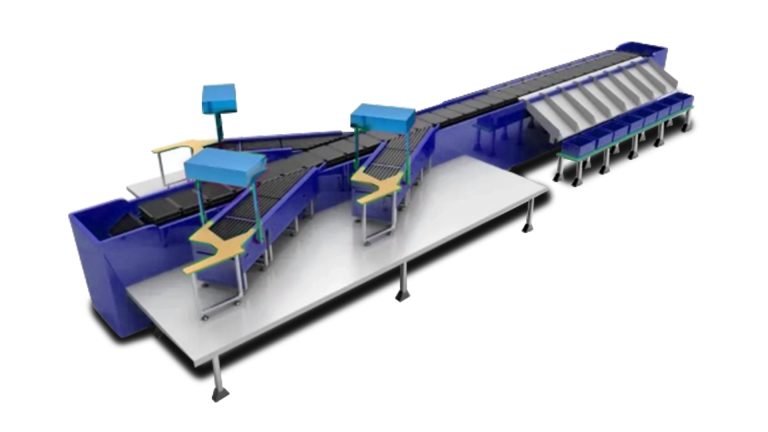

Linear cross belt is a sorter system with high performance, high precision and low energy consumption.

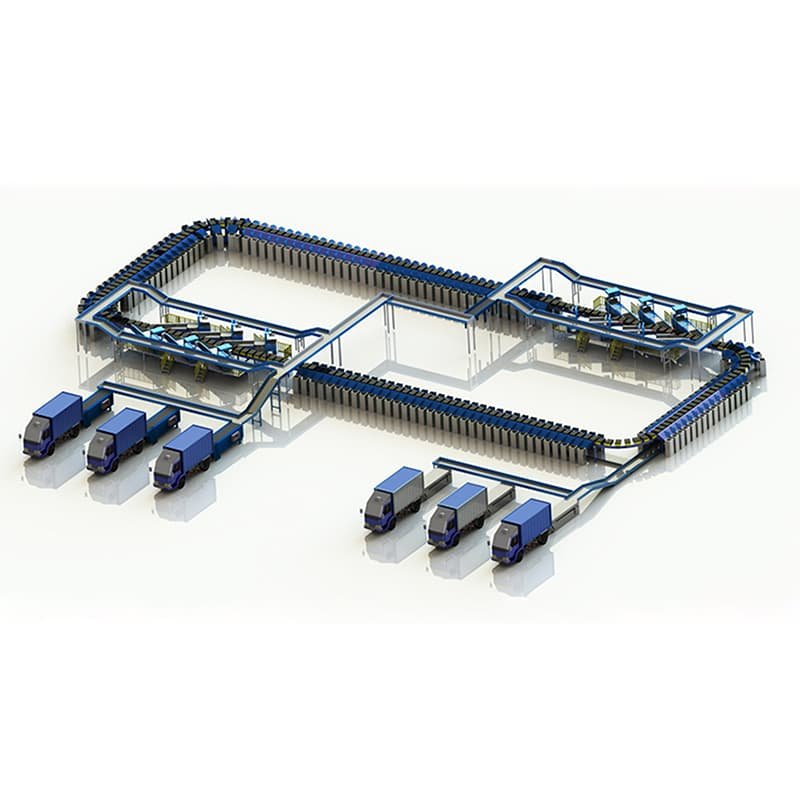

Vertically combined with circular layout, the structure is compact and extremely saves space. Standard modular design, according to customer needs to customize the number of ports, the product is more cost-effective.

Model: Sorter Machine

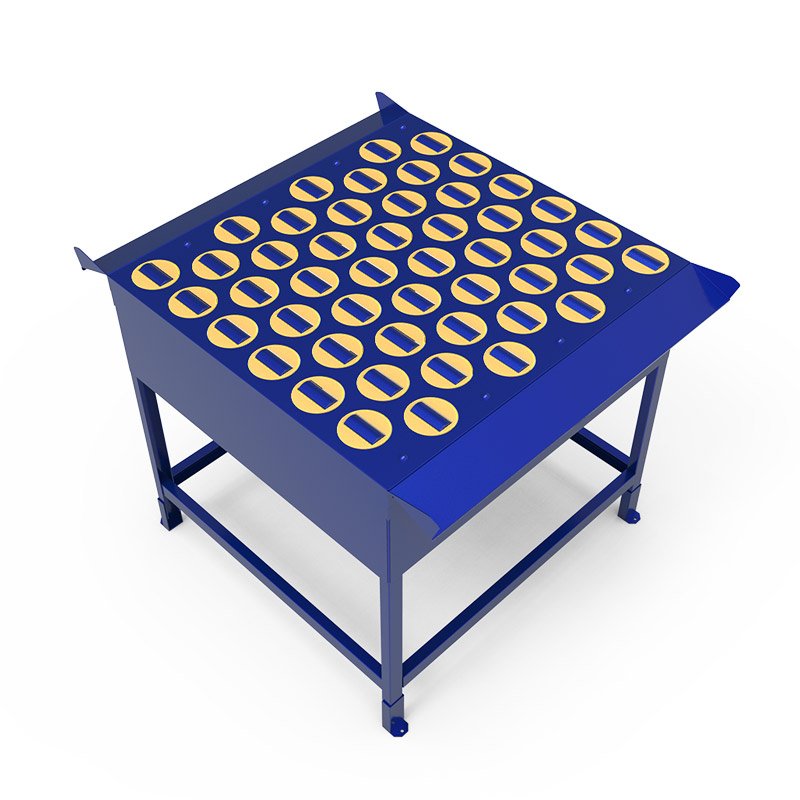

Generally, it consists of four parts : parcels supply system, sorting trolley, parcels delivery system and control system. Supply parcel system: generally manual parcel face sheet facing up, placed on the pulling package section or front static weighing, after measuring the dimension, and then placed on the pulling package section.Sorting trolley: consisting of a trolley and a trolley track;

Parcel delivery system: port (750mm), port electrical, port photoelectric (full port detection), bag collection / cage carriage

The parcels are manually placed on the pulling section with the parcel sheet facing upwards, the parcels pass through the top scanning camera, the scanning system obtains and uploads the barcode information to the headquarters server, the headquarters feedsbacks the parcel drop port information, the parcels fall into the sorting trolley and run to the designated port entrance by the track, and the parcels are dropped into the designated port entrance for collection by sliding the trolley belt left and right.

Supermarket industry, e-commerce industry, clothing and shoes industry industry, fresh distribution industry

It is applied to parcel or product sorting in postal, express, e-commerce, clothing and shoes, 3C and other industries ; suitable for bulk parcel sorting of different sizes, shapes and properties ( except for uneven bottom, rollable parts and light foam parts )

1. Modular structure, easy to assemble and maintain;

2. There are three ways of supplying parts, manual, semi-automatic and fully automatic, for free selection.

3. The main drive adopts magnetic levitation drive mechanism (synchronous linear motor/asynchronous linear motor)

4. With automatic deflection correction function, multilateral detection function, over-edge detection function;

1. Simple and convenient operation, extremely easy to use

2. High sorting accuracy and speed;

3. Low operation and maintenance costs, low energy consumption, short return on capital cycle

4. Small footprint, suitable for long and narrow sites

| Trolley control electric: Panasonic Sliding contact line\brush\collector, etc. (25/28\group) Panasonic Sliding contact rails Leadshine/HongMa/Shengpai 5.5KWLinear motor Leadshine/HongMa/Shengpai 400W48V Electric roller Kinco servo driven XINBEX700*428 belt H1800 Smart Carrier Pallet Flexible organ cover L3000mm track;gantry |

|---|

| Port control electrical: Schneider button/Three-color indicator Siemens/Schneider APT(PLC\LED Leuze photoelectricity Top scan: Hikvision(One camera) |

| Software control/main control cabinet: Siemens/Danfoss frequency converter Huawei / tplink Thousand M Switch Jinhuanyu Transformer Sorting Handover Control Cable Dell WCS specifies the configuration server ( picture / data, sorting / local cache ) Siemens PLC Server data interactive processing, sorting control system Equipment detection, fault diagnosis, maintenance reminder and so on Operating parameter setting, remote management, data statistics, etc. IT-level network supporting equipment, data docking Interconnected intelligent gateway system WEB server network system Industrial network data exchange system Industrial PC _ PC (Lenovo/Dell) SQLsrever database |

| Wireless communication : wireless AP ; Siemens PLC communication interactive detection, feedback sensing, power supply, etc. |

| Main line speed 1.2-2m/s |

| Weighing function front fast hand weighing / can be upgraded to dynamic weighing |

| Maximum sorting efficiency 9000 votes/hour |

| Weighing range 10g-10Kg |

| Trolley size 426mm*700mm |

| Trolley pitch 500mm |

| Grid width 750mm |

| Sorting goods size range 10*50*50-200*400*400mm |

| Sorting accuracy rate 99.99% |

| Controller A full set of Siemens controller solutions (1500, 1200 series PLC) |

| Trolley drive mode Motorized drum Servo drum |