When it comes to managing large quantities of items, a sorter can be a game-changer in optimizing processes, increasing efficiency, and saving time and resources. From warehouses to manufacturing facilities, businesses across various sectors utilize sorters to manage their inventory and streamline their operations. But what exactly is a sorter, and what is its purpose? In this blog post, we’ll dive into the world of sorting machines and explore the benefits they provide.

What is a sorter?

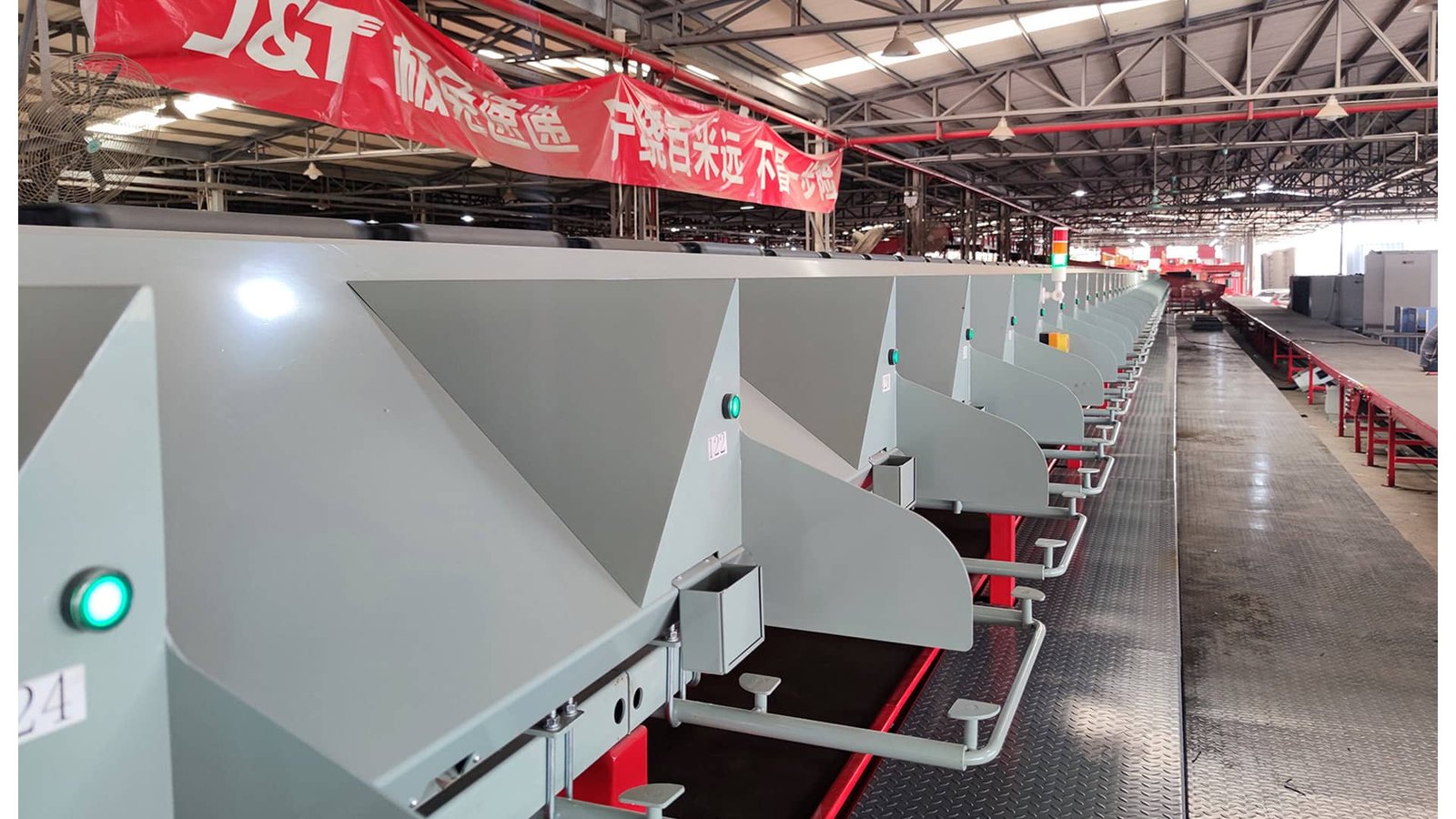

A sorter is a machine that automatically categorizes and separates items into different groups based on predetermined criteria. The criteria could be anything from the size, shape, color, weight, or barcodes of the items. Sorters can either be flat or tilted and can operate at different speeds and capacities to meet specific requirements. Some common types of sorters include conveyor sorters, tilt-tray sorters, cross-belt sorters, and automated storage and retrieval systems (AS/RS) with sorting capabilities.

Why use a sorter?

The benefits of using a sorter in your operation are plenty. First and foremost, a sorter helps to reduce human error and increase accuracy when categorizing and tracking items. A machine is much less likely to make mistakes or overlook key details than a human worker. Additionally, a sorter can significantly speed up the sorting process, allowing for faster fulfillment of orders and increased productivity. By automating the sorting process, operations can also be run 24/7 without the need for breaks or shift changes. Sorters also improve safety in the workplace by reducing the amount of manual labor involved in sorting, which can lead to fewer accidents and injuries.

The different applications of a sorter

Sorters are used in a wide range of industries and applications. In e-commerce and retail, sorters are used to sort orders for delivery by courier companies or in-house logistics. In manufacturing, sorters sort parts and components of machinery as they come off the production line to ensure they are in the correct order before being assembled. In food processing plants, sorters separate different types of food by color, size, or shape to ensure consistent quality. In libraries, sorters are used to sort returned books and return them to the correct location on the shelves. In short, any industry that requires the categorization and separation of objects can benefit from using a sorter.

How to choose the right sorter

When considering a sorter for your operation, there are several factors to take into account. First, you must determine the throughput capacity required for the sorter to handle the expected volume of items. Secondly, you must consider the space you have available and how the sorter will fit into your facility’s layout. Thirdly, you must look at the different capabilities and technical specifications of the available sorters and determine which one best suits your specific requirements. Finally, you need to consider the cost of purchasing and installing a sorter, as well as the potential return on investment over time.

Sorters play a crucial role in optimizing operations in various industries by automating the sorting process and improving accuracy and productivity. There are several types of sorters available, and the choice depends on individual needs and requirements. Whether for handling large volumes of online packages, assembly line parts, or library books, a sorter can help keep inventory organized, improving safety, and reduce costs for businesses. Implementing the right sorter can unlock significant benefits for businesses and position them for future growth and success.