Sorting is a fundamental activity that we do every day to classify things. Whether it’s sorting out your laundry, separating your groceries, or organizing your files, there’s always a need to bring order to the things around us. Sorting plays a vital role in managing warehouses, distribution centers, and logistics operations for businesses. It helps to optimize the utilization of space, improve productivity, and enhance customer satisfaction. In this blog post, we will dive into the world of sorter operations and understand how it can streamline your business operations.

What is Sorter Operation?

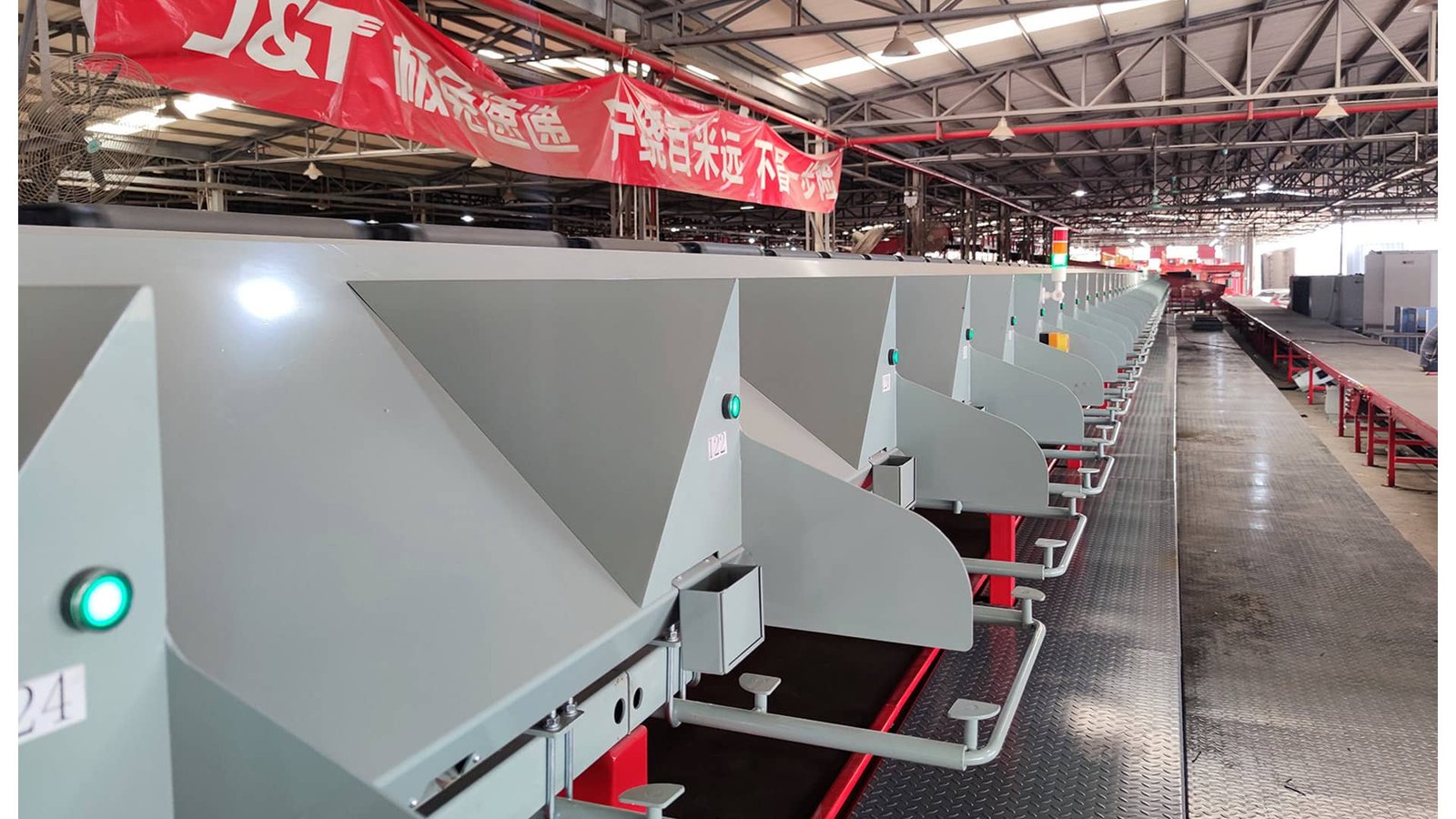

Sorter Operation is a process of automated sorting of products, parcels, or boxes based on predefined criteria such as size, weight, destination, or SKU. A sorter system consists of conveyor belts, sensors, diverters, and control systems that work together to sort items quickly and accurately. The sorter systems can be either linear or circular, depending on the requirement, and the products are screened as based on the criteria programmed into the sorter.

Types of Sorter Operations

There are various types of sorter operations, and businesses can choose what suits best for their specific needs. Some of the common types of sorter systems include:

Shoe Sorter: Bike Sorter uses a series of shoes that angle and position the product to the desired destination. This sorter can handle a variety of products in a single sorter.

Tilt Tray Sorter: In this type of system, trays tilt to guide the product to the required destination. This sorter is excellent for sorting products like poly bags, envelopes, and parcels.

Wide-Belt Sorter: In this system, a wide belt with cutouts underneath helps products fall through to the required lane.

Cross Belt Sorter: Cross Belt Sorter is suitable for items with an irregular shape. In this system, the items are fed onto the vertical conveyor, and the cross belts transport the item to their respective destinations.

Benefits of Sorter Operation

Sorter Operation helps to bring efficiency and accuracy to business operations. Here are some of the benefits that sorter systems bring to your business:

Increased Productivity: Sorter systems can sort thousands of products per hour, automating the sorting process and speeding it up.

Reduced Labor Costs: By automating the sorting process, businesses can save labor costs and reduce the waste of human resources.

Improved Accuracy: Sorting systems help to prevent human errors in sorting, leading to fewer errors and better satisfaction with customers.

Better Space/Material Utilization: Businesses that need to store lots of inventory can better utilize their space by adopting an automated sorter system.

Improved Customer Satisfaction: With a streamlined sorting process, customers receive their orders more quickly and accurately, resulting in higher satisfaction.

AI and Machine Learning Integration in Sorter Operation

Recent advancements in AI and Machine learning have provided an opportunity for sorter systems to be more efficient and intelligent. The sorting processes can be monitored in real-time, and the algorithms can respond proactively to situations. For example, if a particular conveyor line is overloaded, it can divert the product to another line, or it can prioritize urgent packages over standard ones. These intelligent sorters can learn and adapt to the business’s unique requirements, further improving the efficiency of the operation.

Sorting is a crucial activity in streamlining business operations, whether it’s a small retail outlet or a large distribution center. Sorter systems can bring about a lot of benefits, including increased productivity, accuracy, and customer satisfaction. Recent advancements in AI and Machine learning provide an opportunity for sorter systems to become more intelligent and proactive in enhancing the business’s operation. Thus, sorter operation is an essential tool for businesses to streamline their operations and deliver quality services to their customers.