Home » Intelligent Logistics Solution for Express Transshipment Automation

Background

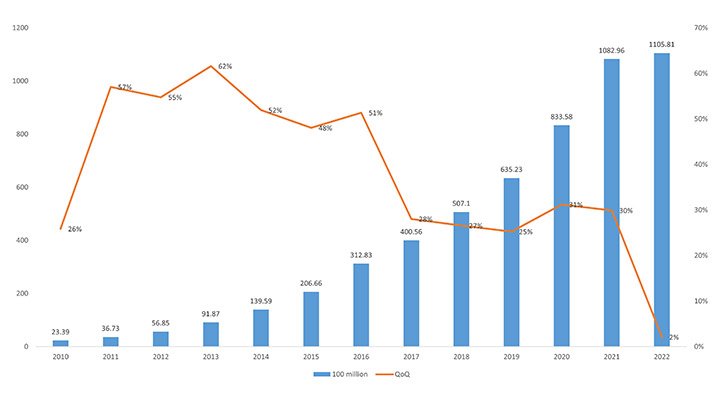

China’s logistics industry has experienced explosive growth over the past decade. According to statistics, in 2010, China’s express packages were 2.339 billion, and in 2021, express packages were 108.296 billion. In 12 years, express packages have increased nearly 50 times, and the express industry has emerged a trillion-level market.In the process of rapid development, the carrying capacity of express logistics enterprises is growing rapidly, and the annual carrying capacity of large logistics enterprises is as high as billions or even tens of billions of pieces.Therefore, the charging method of express carrier, cloud planning, tracking and tracing, cost reduction and efficiency enhancement have become the core issues of logistics enterprises.

In view of the current situation that the number of express transshipment items is huge, the space is limited, the labor efficiency has reached a bottleneck, and the transshipment efficiency can not be improved by increasing labor, automated logistics transshipment instead of intensive manual operation has become an inevitable choice for world logistics enterprises.The automated logistics transshipment scheme can provide accurate billing basis, real-time sorting information, reasonable vehicle management and long-term historical data for express logistics enterprises.As the core system of express transshipment stage, it runs stably and efficiently, with accurate and timely data, providing basic information for express sorting, cost settlement and logistics traceability.

Introduction to the programme

In China, the number of express parcels is still growing at a high speed in recent years, but the unit price of express delivery has been further compressed. Obviously, the scale of the express industry has reached the margin, and logistics enterprises need scientific and technological support to reduce costs and increase efficiency.

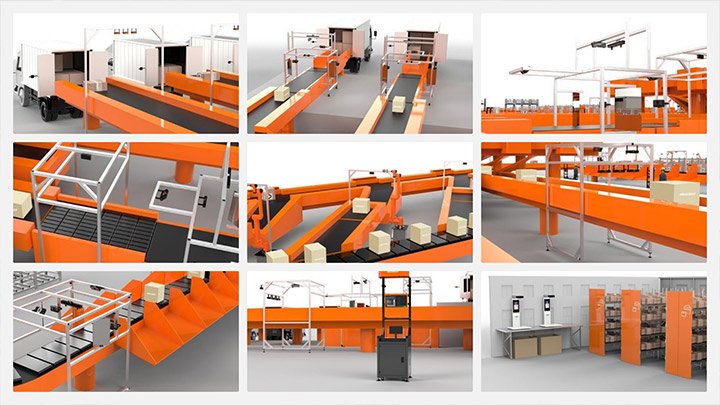

SorterTop automated intelligent logistics solutions include unloading/loading solutions, sorting solutions and intelligent transshipment solutions, aiming at the parcel out/in storage, sorting, temporary storage, transshipment, traceability and other links of express transfer stations, to achieve automatic perception, efficient transportation, accurate sorting and intelligent management and control in complex environments, to achieve the goal of reducing costs and increasing efficiency.It realizes the high automation and intellectualization of logistics links.

The express transfer station is composed of a telescopic belt conveyor, a high-speed belt conveyor, a drop belt conveyor, an interval conveyor belt, a single-piece separation device, a centering module, a DWS detection device, a DWS six-sided scanner, an RFID identification device, the balance wheel sorting machine and an annular cross belt sorting machine, etc., and is matched with a perfect control system and a management system to realize the package from unloading to sorting and then to loading.Automated operation of the entire process.The intelligent logistics solution of express transshipment automation adopts modular design, which can make dynamic adjustment according to the size of the site and the status of the goods, and can meet the peak sorting needs and challenges of multiple trucks unloading synchronously.Accurate sorting, through single separation to control the distance between packages, DWS six-sided scanning omni-directional code reading without dead angle, real-time tracking of package trajectory, accuracy can reach more than 99%.

The scheme applies a number of automated logistics equipment combined with advanced Internet of Things technology to build a standardized, automated and intelligent sorting system.

Programme features

- The scheme adopts modular design, which can be flexibly adjusted according to the site and cargo.

- The scheme adopts DWS five-side scanning and DWS six-side scanning detection equipment and high-speed code reading camera for multi-directional detection, with an accuracy of more than 99%.

- High sorting efficiency. The flexible design scheme of multi-layer cross belt configuration doubles the sorting efficiency and greatly utilizes the site space.

- Highly automated and intelligent, can adjust the degree of automation according to user needs, realize the organic combination of man and machine, and reduce costs

Programme advantages

- The senior engineer conducts field survey and leads the design team to complete the scheme design according to the site conditions.

- On-site implementation and commissioning by delivery engineers to ensure stable operation of the solution, providing on-site technical support services

- Organize preventive maintenance regularly to prolong the service life of the machine

- Multiple emergency prevention programmes to respond to sudden emergencies

- Technical director and R & D team provide timely remote service, cooperate with resident engineers or on-site technicians to solve problems.