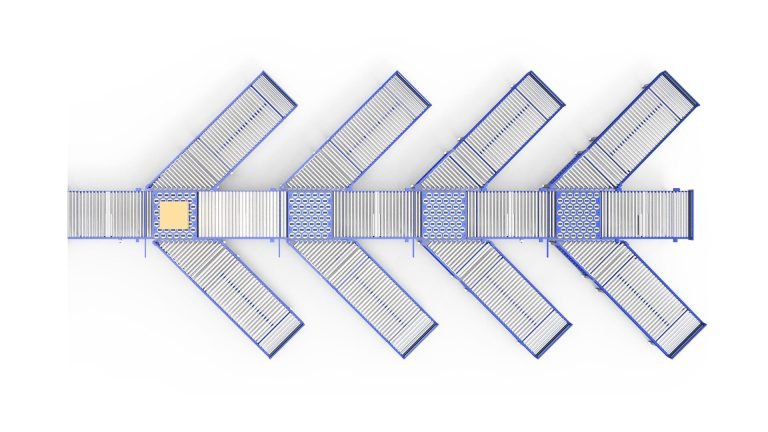

Dimension Weighing and Scanning System( Dynamic DWS) +Sorter Machine

Introduction

Dynamic DWS+ Sorting is an intelligent logistics machine that automatically measures, weighs, scans and sorts goods (parcels) automatically.

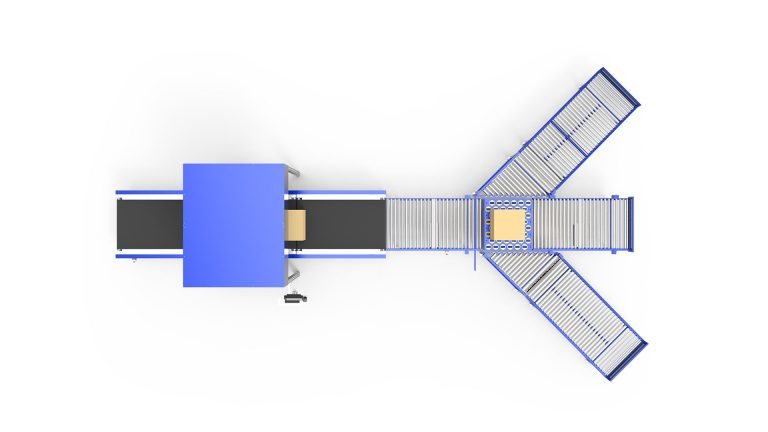

The complete machine consists of a top scan module, a three-stage dynamic scale and a sorter. The top scan module and the dynamic scale collect the volume, weight , and manifest information of the goods (parcels) and feed it back to the IPC upper computer system, where the parcels are handed over to the sorter for sorting in a specified manner through a pre-defined procedure. The information collected by the equipment and the calculated sorting information is consolidated and stored in the IPC for query and export.

Model: DWS

The complete machine consists of a top scan module, a three-stage dynamic scale and a sorter.

Top scan module

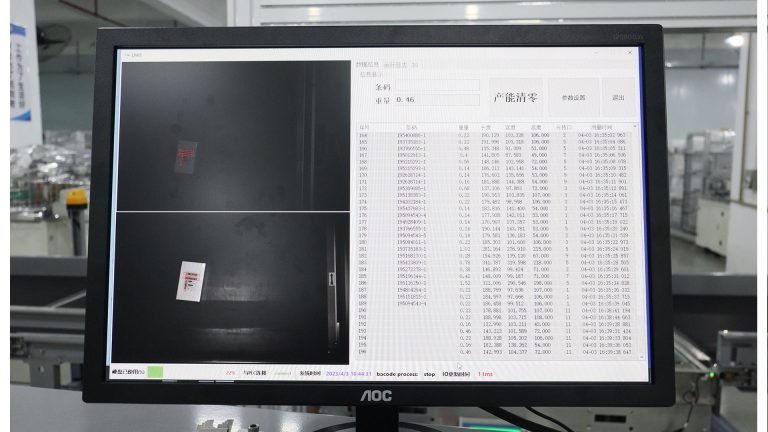

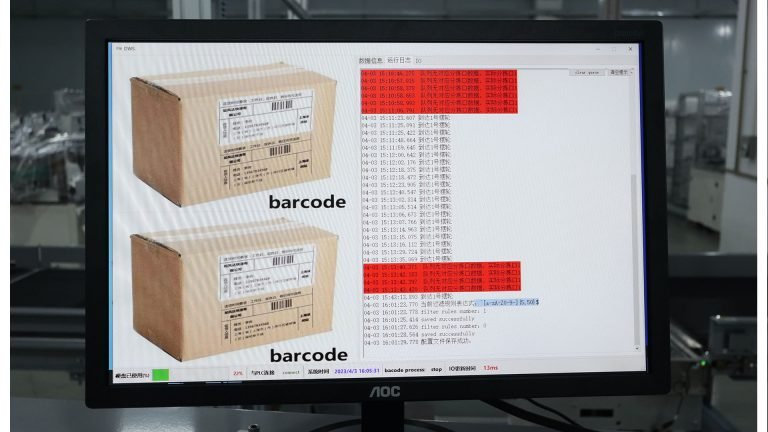

The top scan module consists of a scan module and a line laser module. The scan module consists of a high-speed code reading camera, lens, light source and controller. When the parcel passes through the dynamic weighing, the reading camera is triggered by the sensor to complete the scanning of the parcel and send the data to the computer. We use the high-definition high-speed code reading camera with Hikvision or Dahua, reading the code accurately. While scanning the code, the line laser measurement module uses the laser beam to measure the length, width and height parameters of the object and calculates the volume of the object through mathematical algorithms and sends it to the computer. The line laser measurement has the advantage of high accuracy and height and is independent of the nature of the object’s shape.

Three-stage dynamic weighing

The three-stage dynamic weighing consists of a caching section, a weighing section and an exception handling section. The cache section, also called the packet pulling section, docks the conveyor. The cache section automatically transfers numerous parcels in turn to the weighing section through the speed difference, and the parcels continue to move at a uniform speed as they pass through the weighing section, where the weighing work is completed by the high-precision electronic scales at the bottom, with weighing accuracy within plus or minus 50g.

The top scan module and dynamic scale will send the collected information to the computer, which will automatically calculate based on the preset software, and the parcels in normal state will pass through the machine quickly, while the parcels in abnormal state will be stranded in the abnormal processing section and pass through again after manual checking. All successfully processed information and photos will be saved to the computer has been queried and exported.

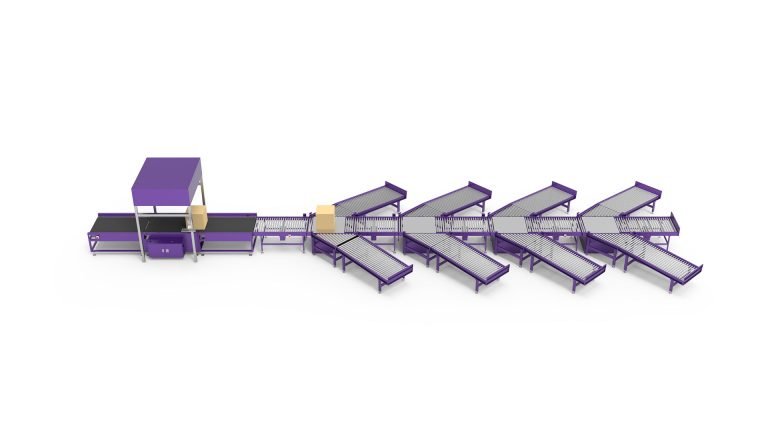

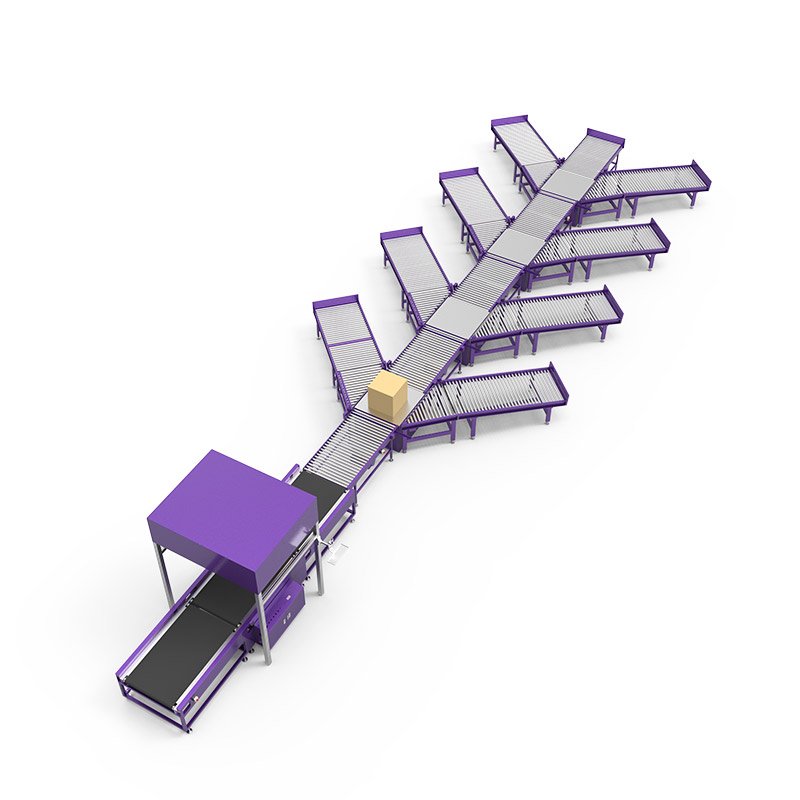

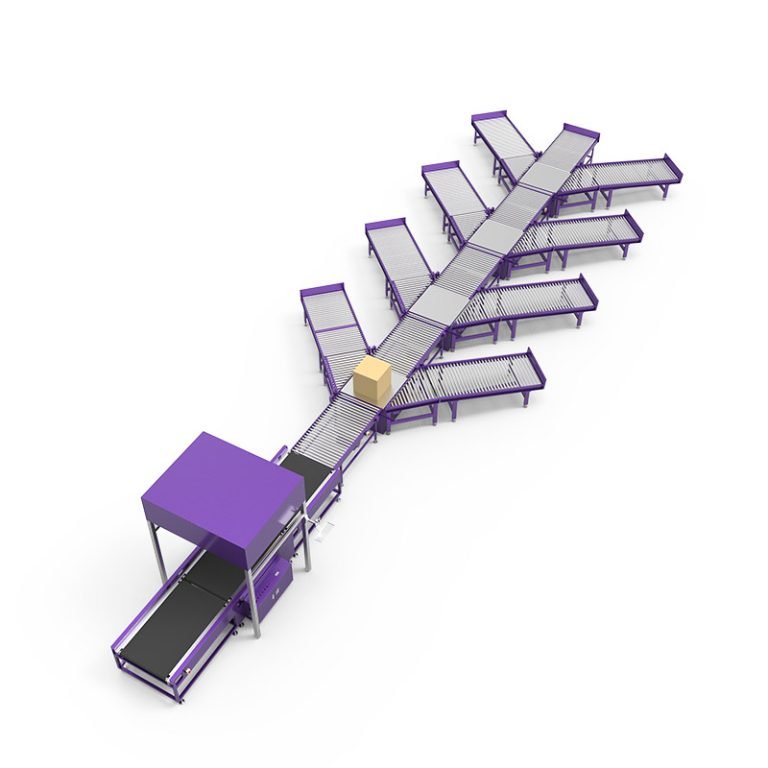

Sorting Machines

After the parcel has been measured, weighed and scanned, it automatically enters the sorting process and the parcel is automatically sorted according to a set program. The user selects the sorting equipment according to the size of the site and the efficiency of the sorting process. There are pendulum wheel sorters, narrow belt sorters, linear cross belt sorters, high speed narrow belt sorters and ring cross belt sorters available. The pendulum wheel sorter and narrow belt sorter require additional power lines and are suitable for smaller sites and are cost effective. They are more expensive than the Pendulum Sorter and Narrow Belt Sorter; the Ring Sorter has a larger footprint and is the most flexible, suitable for large e-commerce, warehouse transfer and airport scenarios. Users can click on the links to find out more about each type of sorting equipment.

E-commerce, express delivery, postal service, fresh cold chain, distribution centres, food, wine and beverages, pharmaceuticals, 3C, electronics,

household chemicals and other industries, Automatic sorting systems for large distribution centres

Taking warehouse transferment as an example, parcels are transferred to DWS equipment through transfer machines or manual placement.

The DWS system automatically collects the volume, weight and face sheet information of the parcels and calculates the parcel sorting grid in advance according to the built-in application,

and after the parcels reach the designated location, the sorting equipment gets a signal and transports the parcels to the designated sorting grid to complete the sorting work,

and then loads the vehicles and transports the parcels to the designated location through the trucks

1. Simple operation, easy to use

2. Adopt Hikvision or Dahua high-speed code reading camera, which can quickly read various barcodes and 2D codes.

3. High precision weighing sensors for accurate weighing of parcels during transport.

4. Can be connected to various ERP or TMS backgrounds

5. Diversified sorting equipment, which can be freely matched according to actual requirements

1. Fast parcel processing speed, easily handling 3000 parcels per hour

2. Branded camera and measurement module for high accuracy of information collection

3. Quality dynamic weighing module, weighing information accurate to within 50g

3. Modular design, easy to upgrade the firmware, simple docking work

4. Stable and highly reliable. After our many upgrades and iterations, the equipment has excellent performance and low failure rate