The world of logistics and warehousing is filled with jargon and acronyms that can leave you scratching your head. One acronym that often pops up in the context of warehouse management is DWS. It is not uncommon to hear terms like DWS scanner, DWS system, or DWS technology. But what does DWS mean exactly? In this blog post, we will decode this elusive acronym and explore its significance in the world of warehousing.

What does DWS mean in warehouse

DWS stands for Dimensioning, Weighing, and Scanning. It refers to the process of capturing the dimensions, weight, and barcode data of a package or shipment using a specialized piece of equipment called a DWS system or scanner. DWS systems are equipped with sensors and cameras that can accurately measure the dimensions of an object and its weight by using load cells. The barcode scanner, on the other hand, reads the barcode printed on the package and saves the data for tracking and inventory purposes.

The main advantage of DWS systems is that they can significantly reduce the time and labor required to process shipments and packages. The traditional way of measuring, weighing, and scanning packages involved several manual steps, which were time-consuming and error-prone. With DWS technology, the entire process is automated, and the data is captured in real-time, eliminating the chances of error and speeding up the entire process.

However, the benefits of DWS systems do not end there. They also offer greater accuracy and precision than manual methods. The sensors and cameras used in DWS systems can measure the dimensions of an object within a fraction of an inch, and the load cells used for weighing are highly sensitive and can detect even the slightest changes in weight. This level of accuracy is critical in industries where even small errors can lead to significant losses, such as e-commerce, retail, and logistics.

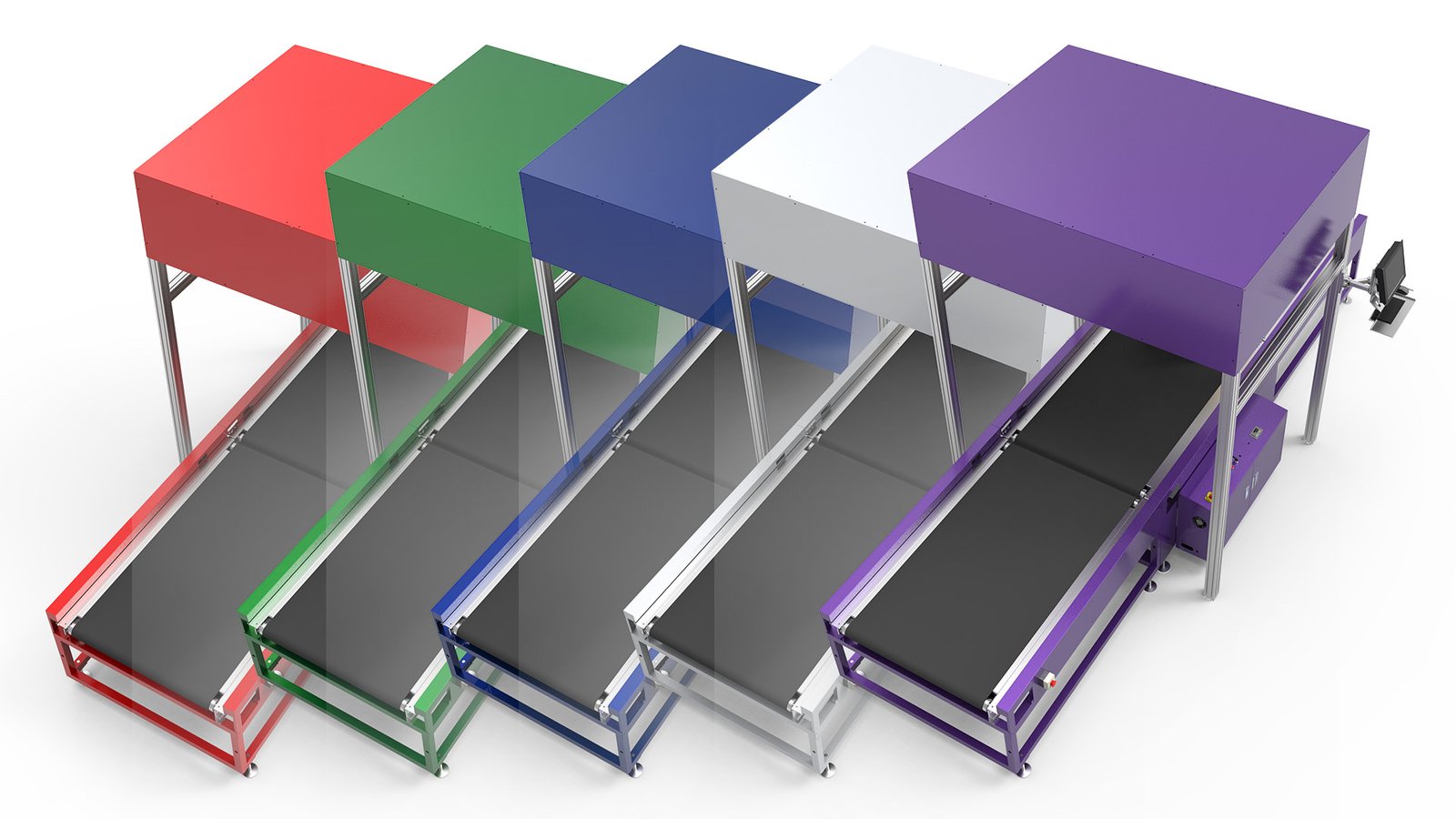

Another advantage of DWS systems is that they offer greater flexibility and scalability. Most modern DWS systems are modular and can be easily integrated with other warehouse management software and hardware. This means that they can be customized to fit the specific requirements of businesses, whether they are handling small packages or bulky shipments. Moreover, DWS systems can handle a high volume of packages per hour, making them ideal for businesses that are experiencing rapid growth.

DWS stands for Dimensioning, Weighing, and Scanning, and refers to the process of capturing the dimensions, weight, and barcode data of a package or shipment using a specialized piece of equipment called a DWS system or scanner. DWS systems offer several benefits to businesses, including increased speed, accuracy, precision, and flexibility. They are the ideal technology for businesses that are looking to optimize their warehouse management processes and reduce manual labor. If you are in the business of warehousing or logistics, implementing a DWS system can significantly improve your overall efficiency and profitability.