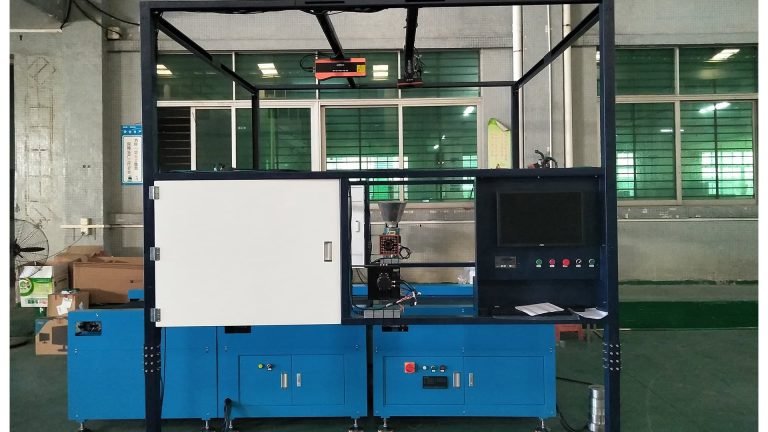

Dynamic DWS Machine (5 side scanning)

Introduction

Dynamic DWS Machine (five-side code scanning) is an extension of the top-side code reading version, which not only has all the functions of the top DWS, but also further improves the sorting efficiency. The code reading cameras on 5 sides of the frame can simultaneously scan 5 sides of the parcel. In this case , the barcode information, dynamic volume and weight data in all directions of the package can be obtained comprehensively, which reduces the requirements for package placement and improves the identification efficiency in unit time. Improve the automation degree and sorting efficiency of enterprise logistics links

Model: DWS

Dynamic DWS Machine (5-side code scanning) consists of the information acquisition unit and the 3-conveyor dynamic scale.

The information acquisition unit

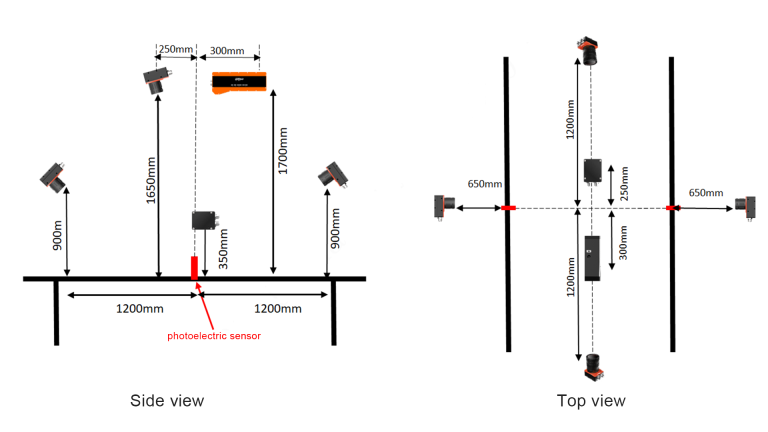

The information acquisition equipment is composed of 5 sets of scanning modules and 1 set of line laser dimension measurement module. The 5 sets of scanning modules are respectively erected at the front, back, left, right and top of the top scanning module rack (as shown in the right figure) to ensure that the package information can be effectively read when the package passes by.The line laser body measurement module uses laser beam to measure the length and width information of the object, and calculates the volume of the object through mathematical algorithm.We use the high-definition high-speed scanning camera and line laser body measurement module in cooperation with Hikvision or Dahua, which can maximize the accuracy of code reading and body measurement.

The 3-conveyor dynamic scale

The 3-conveyor dynamic scale consists of three parts: the cache segment, the weighing segment and the exception handling segment.The buffer section is also called the package pulling section and the docking conveyor. The buffer section automatically conveys many packages to the weighing section in turn through the speed difference. When the packages pass through the weighing section, they continue to move forward at a uniform speed. The high-precision electronic scale at the bottom completes the weighing work. The weighing accuracy is within ±50g

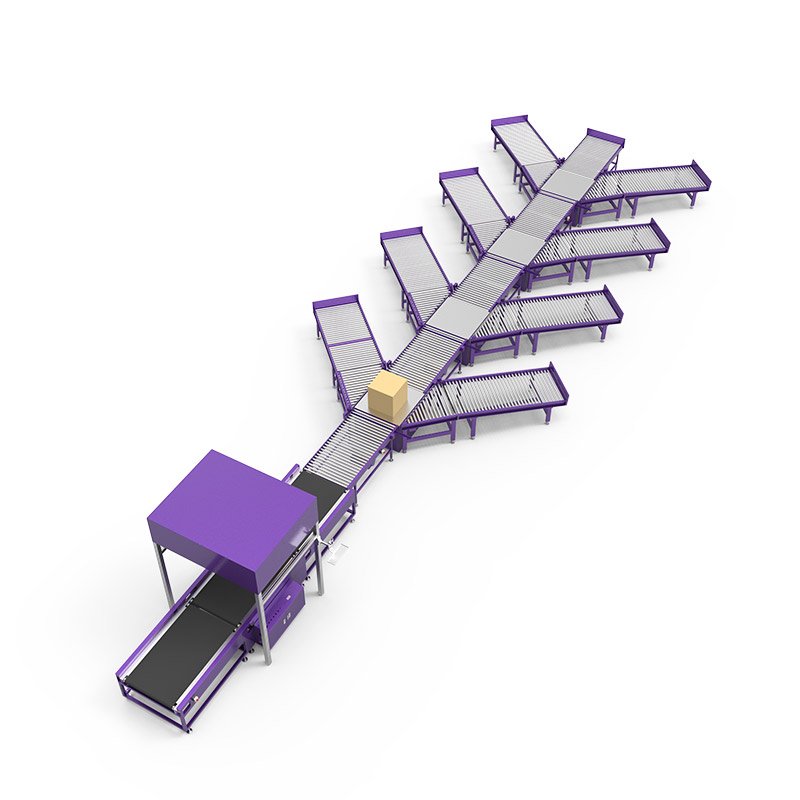

E-commerce, express delivery, postal service, fresh cold chain, distribution center, food, beverage, medicine, 3C, electronics, daily chemicals and other industries

When the package is transported to the weighing section at a constant speed through the feeding conbeyorn, the photoelectric sensor installed at the bottom of the dynamic scale will sense the package first, and trigger the information acquisition equipment and the dynamic scale at the same time.The scanning code module will take photos of the package and read the code (the system will automatically identify the photos with the face sheet information and read the code), the line laser module will measure the length, width and height information of the package, calculate the volume and size information of t he package, and the dynamic scale will measure the quality information of the package, which will be handed over to the upper computer software of the industrial computer for processing.After a series of calculations such as de-duplication and rule comparison, the valid order number is screened out and sent to the background system for query. After the background returns the result, the sorting number of the goods is obtained through rule mapping, and the next sorting step is entered.All the successfully processed goods list numbers, weight information and photos will be stored in this machine for inquiry.

1. Free combination of multi-faceted scanning requirements

2. Continuous and efficient code reading, easy to identify each angle sheet

3. Through its own algorithm, efficient and accurate operation, modular combination of various functions

4. Convenient docking with existing equipment in the site

| 1. Package processing speed is fast, easily upto 6000PPH 2. Code reading rate 99.99% 3. Measuring length and width high precision ± 10mm 4. The bar width minimum 0.2mm. |