Introduction

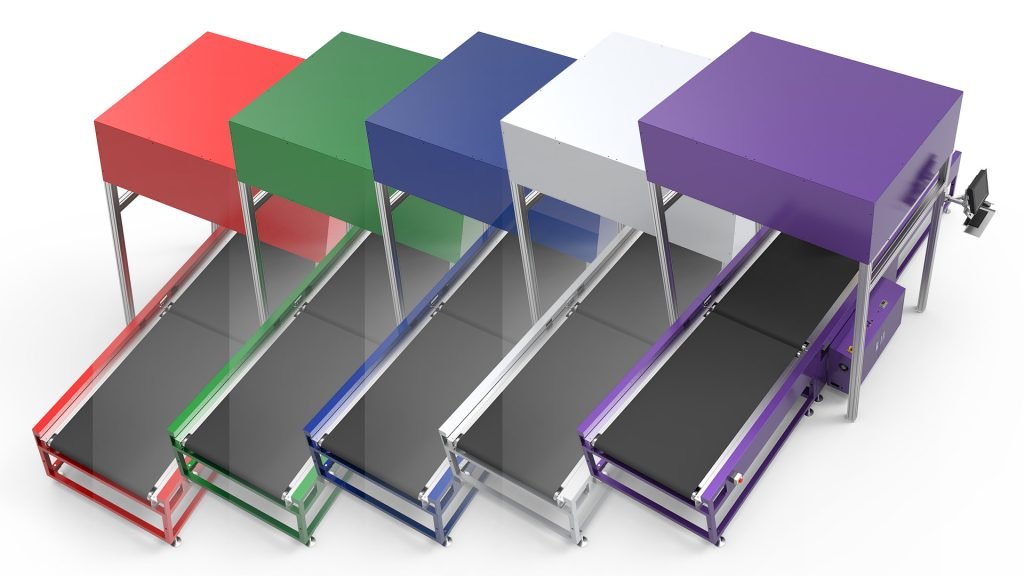

Dynamic DWS equipment is an integrated intelligent logistics equipment that can automatically measure the volume of goods (packages), dynamically weigh the goods, and dynamically scan codes on goods. D stands for Dimension, W stands for Weight, and S stands for Scan. This device can be connected to the system to automatically upload the collected and processed package data, and sorting equipment can be added at the end as needed to improve the processing speed and efficiency

Model: DWS

The whole machine consists of a top-scanning module and a three-stage dynamic scale.

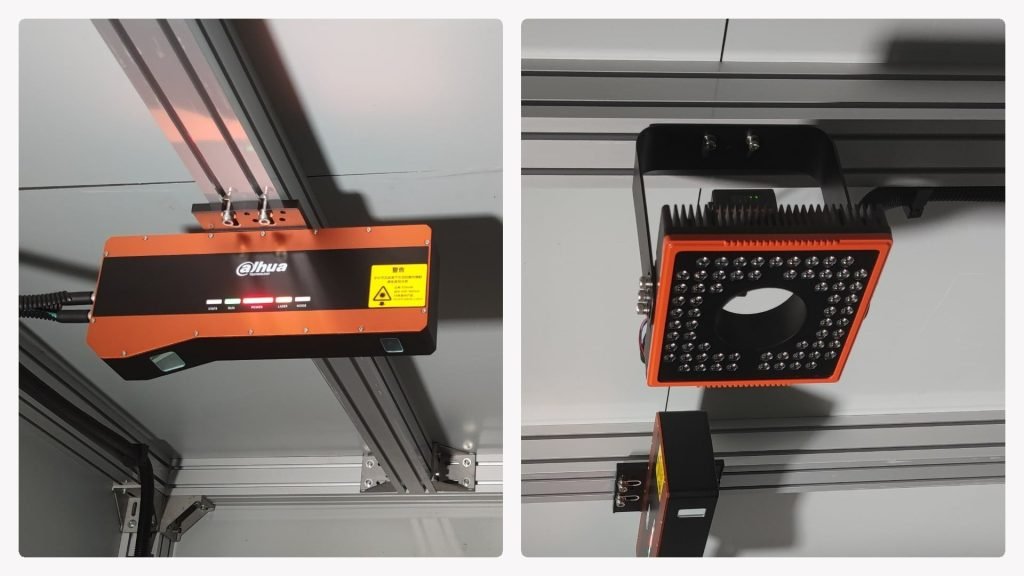

Top scan module

The top scanning module is composed of a code scanning module and a line laser module. The code scanning module includes a high-speed code reading camera, lens, light source and controller. When the package passes the bottom of the top scanning module, the sensor installed on the dynamic scale will trigger the high-speed code-reading camera to take pictures and read the code, and send it to the industrial computer. We use a high-speed high-definition code-reading camera with high-resolution photos and accurate code-reading. At the same time, the line laser body measurement module uses the laser beam to measure the length, width and height parameters of the object, calculates the volume of the object through mathematical algorithms, and sends it to the industrial computer. The line laser measuring body has the advantages of high precision, high degree, and is not affected by the shape and nature of the object.

Three-stage dynamic scale

The three-segment dynamic scale consists of a cache segment, a weighing segment and an exception handling segment. The buffer section is also called the pulling section. It is connected to the conveyor. The buffer section automatically separates many packages one by one through the speed difference and transmits them to the weighing section. When the packages pass through the weighing section, they continue to move forward at a constant speed, and the high-precision electronic scale at the bottom completes the weighing. For packages work, the weighing accuracy is within plus or minus 50g.

The top-scanning module and the dynamic scale send the collected volume, weight, and barcode information to the industrial computer, and the upper computer software running on the industrial computer performs calculations in a preset way. The packages in the normal state pass through the machine quickly, and the packages in the abnormal state stay in the exception handling section of the three-stage dynamic scale, and pass it after manual inspection. All successfully processed cargo order numbers, weight information, volume information and photos will be saved to the machine and have been queried and exported.

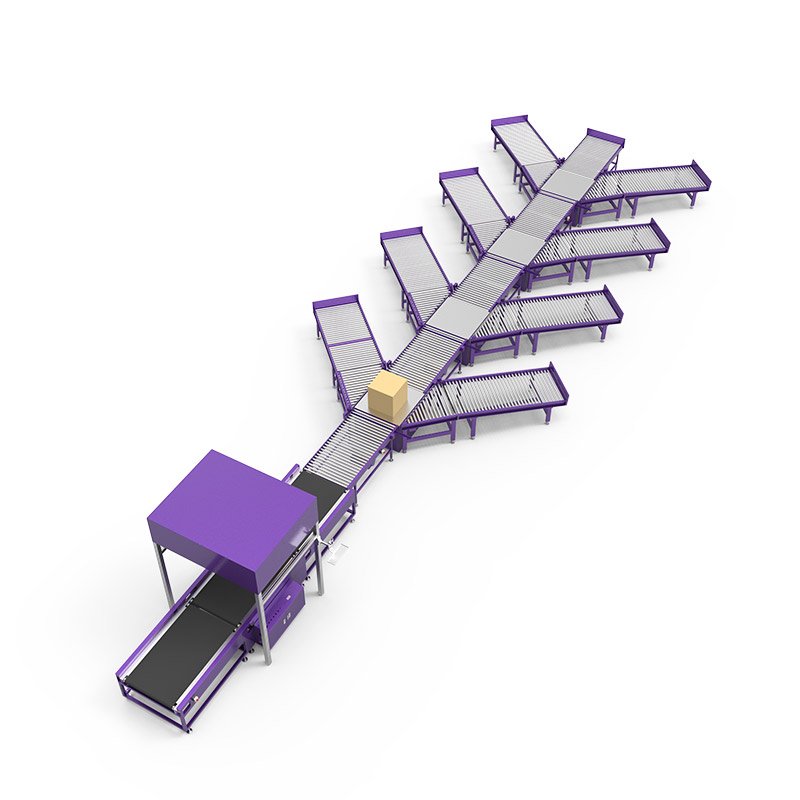

E-commerce, express delivery, postal service, fresh cold chain, distribution center, food, beverage, medicine, 3C, electronics, daily chemical and other industries Automatic sorting system of large distribution center

The workflow can be inserted into the picture shown on the right. Taking storage and transshipment as an example, after the truck arrives at the unloading area, it is connected to the telescopic belt conveyor and docked with the DWS equipment. According to the set program, the telescopic belt conveyor will send the package to the DWS equipment. When the package is dynamically weighed, it will simultaneously collect the package’s volume, weight and face sheet information, and then enter the sorting process.

1. Efficient code reading, easy to identify face sheet information

2. Multi-sided code reading can be freely combined, optional 3-sided, 5-sided, 6-sided code reading

3. Through its own algorithm, efficient and accurate operation, modular combination of various functions

4. It is convenient to connect with the existing equipment of the site

1. The package processing speed is fast, and it can easily handle 6000 packages per hour

2. The code reading rate can reach 99.99%

3. Measure the length and width with high precision ±10mm

4. The barcode supports the smallest 0.2mm”