Dimension, Weighing and Scanning System(DWS)

Home » DWS

DWS equipment is a kind of intelligent logistics equipment which integrates automatic volume measurement, (dynamic) weighing and dynamic code scanning of goods (parcels).According to the degree of automation, it can be divided into dynamic DWS and static DWS.

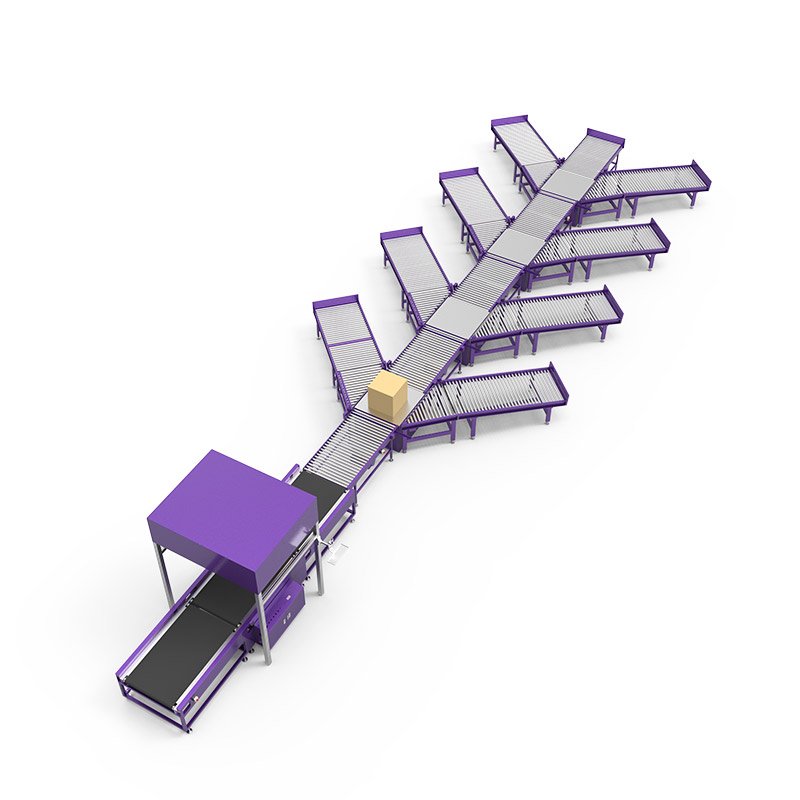

Dynamic DWS equipment can generally be applied to automatic process operations in large warehouses. A complete set of sorting system can be formed by DWS equipment and sorting machines, which can comprehensively improve the automation and sorting efficiency of enterprise logistics links. Dynamic DWS according to the number and position of the scanning modules, it can be divided into single-sided scanning, three-sided scanning,five-sided scanning and six-sided scan, Dynamic DWS (single-sided scanning) is equipped with a set of scanning module and a set of line laser body measurement module on the top of the rack, which can dynamically read the information of the package from the top side. Dynamic DWS (six-sided scanning) has six sets of scanning modules, which can be flexibly configured to cover the scanning on six sides without dead angle, greatly reducing the difficulty of package placement and improving the identification efficiency in unit time.

Static DWS equipment is generally used in semi-automatic operation environment. It is necessary to manually put the package into the measurement area of the machine. The machine will automatically collect the volume, weight and face sheet information of the package and store them in the computer. It is often used for automatic delivery and pick-up of express delivery sites, and for warehousing of a small amount of goods in and out of warehouses. It has the characteristics of small floor area, movable operation and high flexibility.

Equipment application

In the traditional mode of parcel data information collection, it usually needs many manual links, such as ruler measurement, volume calculation, weighing, manual recording and so on, which is time-consuming and laborious, and the measurement data will also have inaccurate measurement, data entry errors and omissions, which can not meet the storage and transshipment of modern large quantities of parcels. It is an inevitable trend that DWS equipment with high speed and high precision will replace manual work.Because of its small size and strong flexibility, static DWS is widely used in automatic delivery and pick-up of express delivery stations, in and out of small batches of small commodities in warehouses, and in some scenarios where commodity information needs to be recorded. Dynamic DWS is suitable for scenarios that require efficient and accurate handling of large quantities of parcels, docking sorters and conveyor lines, and streamlining and automating warehouse operations. SorterTop’s DWS equipment and sorting equipment are widely used in e-commerce, express delivery, postal service, fresh cold chain, distribution center, food, beverage, medicine, 3C, electronics, daily chemicals and other industries.

Machine structure

The dynamic DWS consists of a top scan module and a three-stage dynamic scale. The top scanning module is responsible for the body measurement and code scanning of the package, which are respectively carried out by the line laser body measurement camera and the code scanning camera.

The three-stage dynamic scale consists of a buffer section, a weighing section and an exception handling section. The weighing section is equipped with four sensors, which are responsible for the dynamic weighing of the package. Body measurement, weighing and code scanning are all carried out in the weighing section of the three-section dynamic scale.The linear laser measuring body of the dynamic DWS can be replaced by a grating measuring body, and the grating measuring body is erected between the buffer section and the weighing section.

The static DWS can select whether to configure the body measuring module and the weighing module according to the actual requirements, and can also configure the conveyor belt on the weighing module to realize the sorting function

How does the DWS system work

The dynamic DWS is triggered by the photoelectric sensor on the dynamic scale. When the package arrives at the designated location, the top scanning camera and the body measurement camera start to work. The scanning camera automatically takes pictures. After the preset program obtains the image, the decoding algorithm is used to decode it to obtain the content and location information of the barcode or two-dimensional code.

The length, width and height of the package are measured by a line laser body measurement camera or a grating, the collected point cloud data is processed by software, and after interference points are removed, the minimum external cuboid is obtained to be the size of the package.

Weighing is obtained by means of a load cell and a weighing instrument. When the bar code, volume and weight are obtained, data fusion is carried out, the fused data is transmitted to the management system according to the required interface protocol according to the interface requirements, and the volume, weight and face sheet information is stored in a computer for convenient inquiry and export.

Can the DWS systems integrate with other warehouse management systems

DWS equipment can be connected to the warehouse management system. Customers are required to provide API interface description documents, and our software engineers will write the interface program.

How much would the DWS system cost

Our DWS equipment is characterized by high efficiency, high precision and high stability. If you are interested in the product, you can contact us to get the details of the equipment and get the best price.

The Key benefits of a DWS system

Provide accurate data information for the freight settlement of express parcels, such as charging according to the Volumetric weight or the actual weight. The Volumetric weight refers to the volume weight obtained by dividing the volume by the coefficient. Generally, the coefficient is 6000-8000;

DWS+Sorting system can prevent errors in the distribution and picking of parcels in the warehouse, and optimize the control of parcel distribution, picking and matching processes

Avoid all kinds of human errors, such as code scanning errors, data entry errors, etc., and can reduce the labor intensity of workers.

High speed and efficiency

Dockable WMS、ERP Or other management systems to facilitate data management and process tracking